Commercial Treatment Plants

We offer experienced, peace of mind installation for all commercial sewage treatment plants. Our engineers guide you through the process while sharing their wealth of experience to ensure all of your property’s requirements are carefully considered.

Sewage treatment plants are the regulation-approved method when dealing with off-mains sewage treatment. Many business premises still use septic tanks or even soakaways to discharge partially treated wastewater, which can be largely detrimental to the environment and fail regulation requirements.

For peace of mind, it is always best to check the sewage system of your property, and we will happily advise on septic tanks, holding tanks, soakaways, and any other type of sewage treatment system you have. We believe in doing the best for our environment and your business, which is why we work as efficiently as possible to improve Septic Tanks, Holding Tanks & Treatment Plants to the latest regulation standards as soon as possible.

Typically 4-5 days for installation and 1 day FREE above-and-beyond finishing service.

We use only the most reliable sewage treatment plants. These well proven, reliable systems come with a 25-year manufacturer guarantee.

Just a few of the benefits of using these BioPure systems over other manufacturers are:

• No mechanical parts

• Virtually maintenance free

• Low wattage pump means running costs are as effective as possible

• Less frequent emptying (manufacturer recommended every 3-5 years)

*Information below is from our recommended manufacturer website

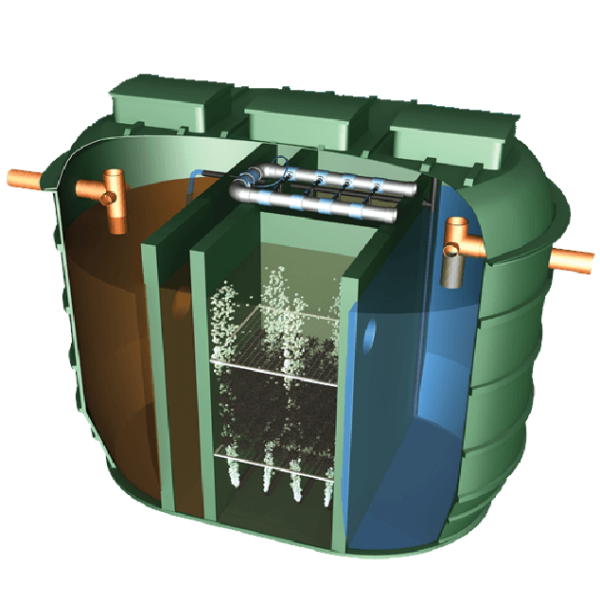

The Bio-Pure Flowpath for Commercial, Industrial or larger off mains applications

We Build It Ltd have developed its range of package Sewage Treatment Plants utilising proven SAF (submerged aerated filter) technology for maximum performance and reliability using the most reliable energy efficient aeration blowers with a prolonged integral flow path system to maximise effluent retention time and quality.

Our standard plant range offers treatment to a 30mg/l BOD: 20mg/l SS effluent quality standard with options for 30mg/l NH3 effluent quality.

All our treatment plants are designed in accordance with the British Water Code of Practice for flows and loads, the Bio-Pure FlowPath range can be designed to meet your population requirements.

The plants can be single or modular tanks depending on population and consent requirements.

Features And Benefits

The Bio-Pure Flow Path commercial sewage treatment plant contains, a two stage primary settlement zone designed to settle coarse and non-biological loadings. Sludge will build up in these zones and require moving periodically.

The Settled effluent will then discharge forward into the bio-zones. Each segment field contains a high percentage of filter media, where biological treatment performs, due to a high oxygen input. Once treatment has taken place the multiple bio-zones, the effluent is discharged into the final humus tank, where it settles before flowing via the outlet.

Occasionally an amount of settled humus sludge is returned to the first primary zone.