Which System Do I Need?

*Information from our recommended manufacturer website

DO YOU NEED A GRAVITY OR PUMPED DOMESTIC SEWAGE TREATMENT PLANT?

What is the difference between gravity and pumped?

Gravity:

Our Bio-Pure gravity sewage treatment plants use gravity to discharge the processed water into the allocated discharge point. Providing the discharge point is lower than the outlet a you will be fine.

Pumped:

The Bio-Pure pumped sewage treatment plants are for situations when gravity cannot take the discharge water to its discharge point using gravity alone. Our pumped sewage treatment plants can pump the discharge water to locations that are higher than the outlet.

WHAT IS THE BIO-PURE SEWAGE TREATMENT PLANT AND HOW DOES IT WORK?

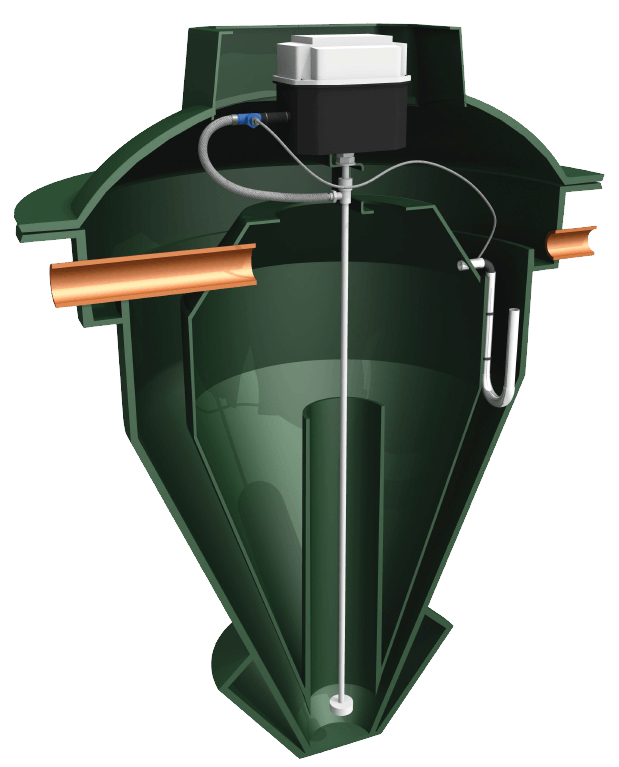

The Bio-Pure is a fibreglass conical shaped tank that is used for domestic sewage treatment. The Bio-Pure works on the successful and simple extended aeration method, which means that the solids are treated as well as the liquids. The extended method that we use means that the sewerage is aerated for a minimum of 24 hours. Many other sewage systems only treat the sewage for a few hours. Treating the solids means that the Bio-Pure only needs emptying every 3-5 years typically, making it a simple and easy solution for sewage treatment.

The unit is available in 10 sizes to cater from 1 to 50 persons and can be used for single houses, renovations, barn conversions, small communities, industrial units and camping sites. The Bio-Pure can therefore serve both domestic and commercial properties that have no access to mains drainage. The Bio-Pure is also now available with an integrated pumped outlet.

HOW DOES THE BIO-PURE DOMESTIC SEWAGE TREATMENT PLANT WORK?

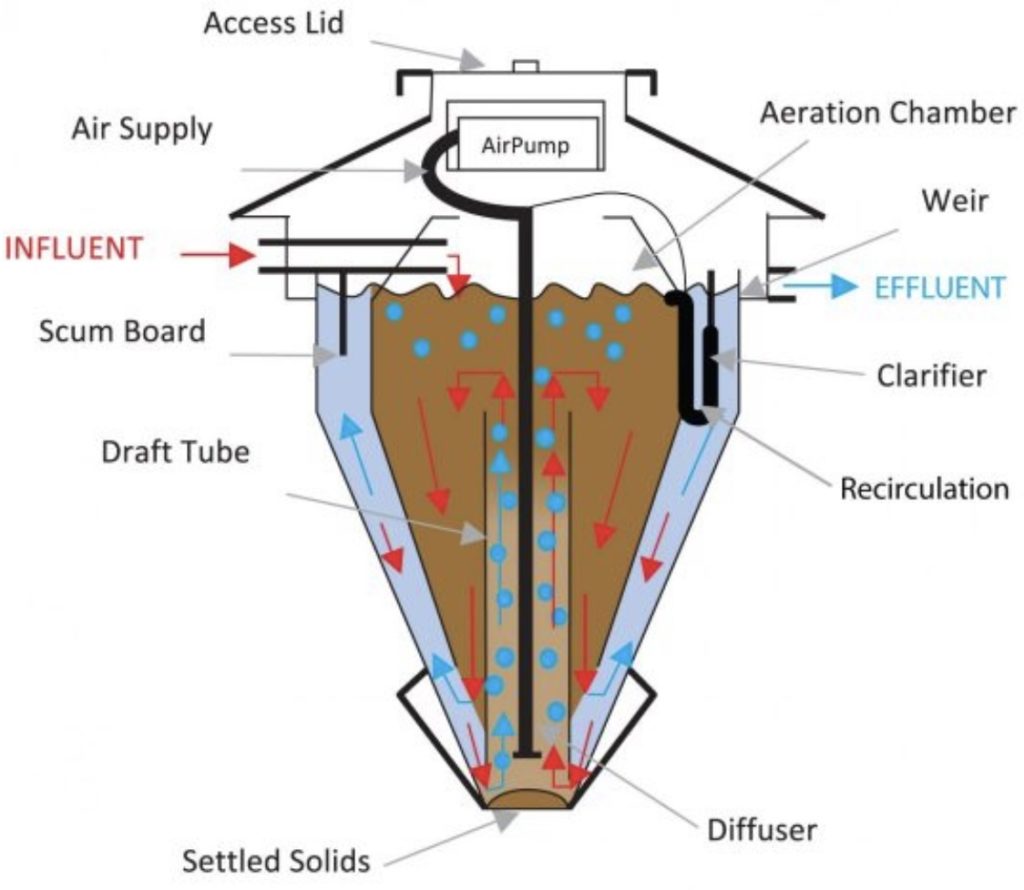

The Bio-Pure is a two chamber unit and consists of a conical tank, with an inner circular aeration chamber inside, which is open at the base.The space between the inner and outer tank is the clarifier chamber.

The draft tube is positioned 100 mm from the base of the clarifier, extends up into the aeration chamber. Air from the compressor housed under the lid is piped to a diffuser in the draft tube.

Raw sewage enters the aeration chamber through the inlet pipe, flowing into the centre of the chamber. Air surging up from the draft tube aerates the sewage, causing an aerobic bacterial colony to establish and digest the organic matter.

As more raw sewage enters the chamber through the inlet pipe, an equal amount of effluent displaces through the open bottom into the clarifier (outer tank).

The quiet conditions in the clarifier allow all the suspended solids to sink to the base of the clarifier and they are drawn back up the draft tube by the upward flow of air for further digestion in the aeration chamber.

The clear effluent rises to the top of the clarifier and passes over a weir into the outlet pipe and is disposed of through a water course or soak away. Further more the Bio-Pure constantly recycles the sewage via gravity and achieves nearly total solids digestion.

Most sewage treatment units consist of three chambers, the first one being a Primary Settlement Tank where the solids form a septic sludge. They require regular emptying by tanker. Because the Bio-Pure digests the solids as well as the organic matter in the liquid, the unit has a much longer emptying interval than any three stage unit. The interval is 3 to 5 years.

The Bio-pure is 96% efficient thus allowing long intervals before de-sludge is required. The waste water is cleaned to a standard of 20 mg/l biological oxygen demand and 30 mg/l suspended solids, meeting the usual discharge level requirement.

The Bio-Pure is fully EN 12566-3 certified

THE PROCESS OF TREATING THE SEWAGE IN 6 SIMPLE STEPS:

- Sewage enters the inner chamber via the inlet pipe

- Air surges up from the draft tube to aerate the solids and liquids for a minimum of 24 hours

- More sewage enters the inner chamber and an equal amount of effluent displaces through and then into the outer chamber (at the bottom of the inner chamber)

- Suspended solids sink to the base of the clarifier and are drawn back up the draft tube for further digestion

- A small quantity of settled effluent from the top of the outer ring clarifying chamber, is drawn back into the centre aeration chamber by a simple airlift system for further digestion.

- Clear effluent rises to the top of the clarifier and passes over the weir into the outlet pipe

WHAT SIZE SEWAGE TREATMENT PLANT DO I NEED?

Sizing and Regulations

In order to work out which Domestic Sewage Treatment Plant is suitable for your property, you must abide by the British Water flows and loads guide. The table of the loading’s on the guide, set out the suitable sizes of treatment plants for different types of property.

A domestic dwelling is fairly straightforward to work out. This is usually the number of bedrooms in the property plus two. For example, a three-bedroom house becomes five (requiring a Bio-Pure 1 Domestic Sewage Treatment Plant). However, if the Sewage Treatment Plant is required for more than one property, then two must be added for each dwelling.

For example

a two-bedroom house plus two = four

a three-bedroom house plus two = five,

and a four-bedroom house plus two = six,

Add them all together = fifteen (4+5+6=15). This will require a Bio-Pure 4 Sewage Treatment System.

For a non- residential property, the size of the Bio-Pure required will depend on the purpose of the property. Please contact us and we will be able to work out the correct size Bio-Pure required for your needs.

THE COSTS OF RUNNING OUR BIO-PURE SEWAGE TREATMENT PLANTS

De-sludging costs

The Bio-Pure Domestic Sewage Treatment Plant needs to be de-sludged (emptied) on average every 3-5 years. The size and usage can impact on the emptying intervals. Costs on de-sludging can vary.

Electricity

Yes the Bio-Pure system uses electricity to operate 24 hours a day, 365 days a year, you may be interested to know roughly how much the Bio-Pure will cost you to run. Here we can give you a simple formula to work this out.

Watts (of pump) × 24 (hours) × 365 (days) ÷ 1000 × price of kilowatt

For example, if you had a Bio-Pure 1 Domestic Sewage Treatment Plant, you would be using a 44 watt pump, and if your electricity was 11p per kilowatt the total cost would be £53.96

Please note that we can not give you an exact figure as to the cost of running the system, as this will depend on certain factors. You should check the price (per kilowatt) with your own electricity provider, as how much the Bio-Pure sewage treatment system will cost to run will depend on how much you pay for your electricity. This could be more or less than 11p per kilowatt. This depends on location and service provider.

Below is a rough guide on how much each of the 10 Bio-Pure sewage treatment systems will cost to run on the price of 11p per kilowatt.

COMPARE OUR SEWAGE TREATMENT PLANTS & SEPTIC TANKS

Below you will see a table showing how the Bio-Pure Sewage Treatment Systems and its extended aeration method of treating sewage fairs against a three stage unit and a traditional septic tank.

The Bio-Pure range have been specifically designed to overcome many of the associated problems with a three stage unit and a septic tank. The Bio-Pure systems are an affordable, high quality sewage treatment plant, with a long term guarantee making it the most practical purchase.

| FEATURES | BIO PURE | THREE STAGE UNIT | SEPTIC TANK |

|---|---|---|---|

| Easy Installation | Yes | Sometimes | Sometimes |

| Concrete Required | No | Mostly | Yes |

| Suitable for a high water table | Yes | Yes | No |

| Visually Unobtrusive | Yes | Sometimes | Sometimes |

| Internal Moving Parts | No | Mostly | No |

| Where can I discharge to? | Watercourse, soak away, ditch | Watercourse, ditch etc | Soak away, reed bed |

| Clean effluent | Yes, very | Yes | No |

| Electricity required | Yes | Yes | No |

| Smelly primary settlement chamber | No | Yes | Yes |

| Emptying interval | 3-5 Years | Annually | Annually |

| Rough electrical cost per annum | £48 | £80 | N/A |

Sewage Treatment Plants vs Septic Tank

The Bio-Pure sewage treatment systems can be discharged directly to a watercourse or groundwater. When you consider whole life costs they are lower priced, smaller and cheaper to install with less pollution.

Your local authority and/or the Environment Agency can refuse septic tanks and may specify a package treatment plant in many areas of the UK, it is essential to check what is acceptable, can advise you every step of the way.

The traditional septic tank may seem very cheap initially, however you will require a soakaway to discharge because the final effluent is not clean enough to discharge into a watercourse or ditch etc. A soakaway for a septic tank can be problematic because a sufficiently large area of land is required, and not all areas are suitable for a soakaway.

The life expectancy of a soakaway from a septic tank is roughly 10 years compared to 25 years from a packaged sewage treatment plant. Soakaways are prone to blocking from a septic tank due to unclean effluent.

The Bio-Pure may therefore be a better solution for your wastewater treatment and possibly cheaper than installing a septic tank.

Discharges from septic tanks to a watercourse are not allowed under the general binding rule. If you have a septic tank that discharges directly into a watercourse you will need to replace or upgrade this by 1st January 2020 or when you sell your property if before this date. If the Environment agency find evidence that the watercourse is being polluted, you will need to replace the tank earlier than January 2020. Typically you will be given a year to arrange for a Treatment Plant Installation, however, this is agreed upon on a case by case basis.